- Online only

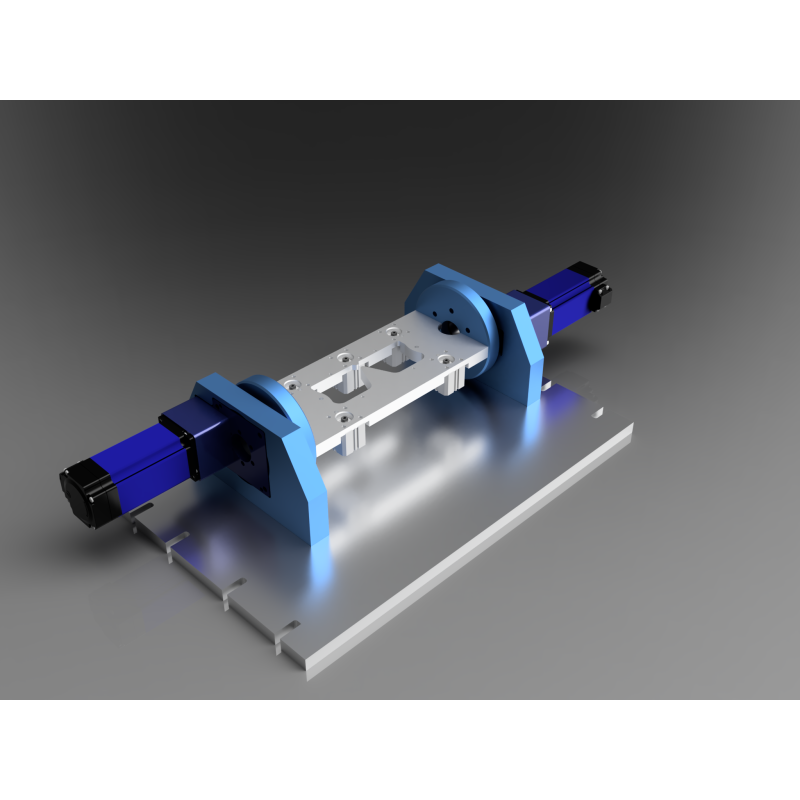

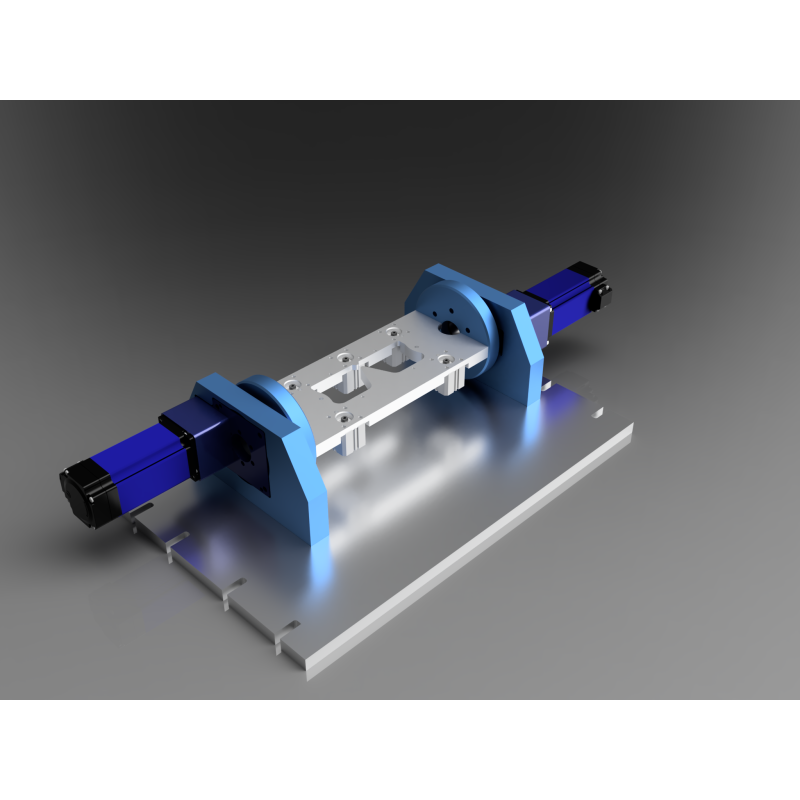

Rotary axis specially designed for making glasses.

Fits all of our CNCs

Includes the 5-point acetate labs pneumatic clamping system. (Minimum 5 bar compressor required)

Rotation ±180°

Counter Torque: 60nm. (The counter torque makes it possible to oppose the cutting force induced by the X Y Z axes)

Repositioning tolerance: 5 arcsec

Step value: 0.18°

• 0°requested. 0° obtained

• 20° requested, 19.98° Obtained: 111.11*0.18° in theory. That is 111 steps of 0.18° -> 19.98°

• 90° requested / 90° obtained. (500 ps of 0.18°)

Rotation speed: 500°/min

Non-contact referencing sensor allowing easy finding of the horizontal.

2x Servo motors NEMA 23 60v 3nm. - Harmonic reducers 1/10

Contact us for integration into your controller box.

Delivered with the postprocessor for fusion360 as well as a 4-axis program model (SoliidWorks with supplement) and 4 hours of online training

Continuous 4-axis machining or rotation of the A axis and static XYZ, A machining.

Rotation speed

Cutting from inside and outside

The rotating axis is very useful for making branch junctions with the tenon inclined according to the pantoscopic Face/Branch angle.

Supplied with the adapted FUSION 360 or SolidWork post-processor and 4 hours of remote training