2 × 12 Eyewear Polishing Barrel – Acetate Frame Finishing | Optical Workshop Equipment

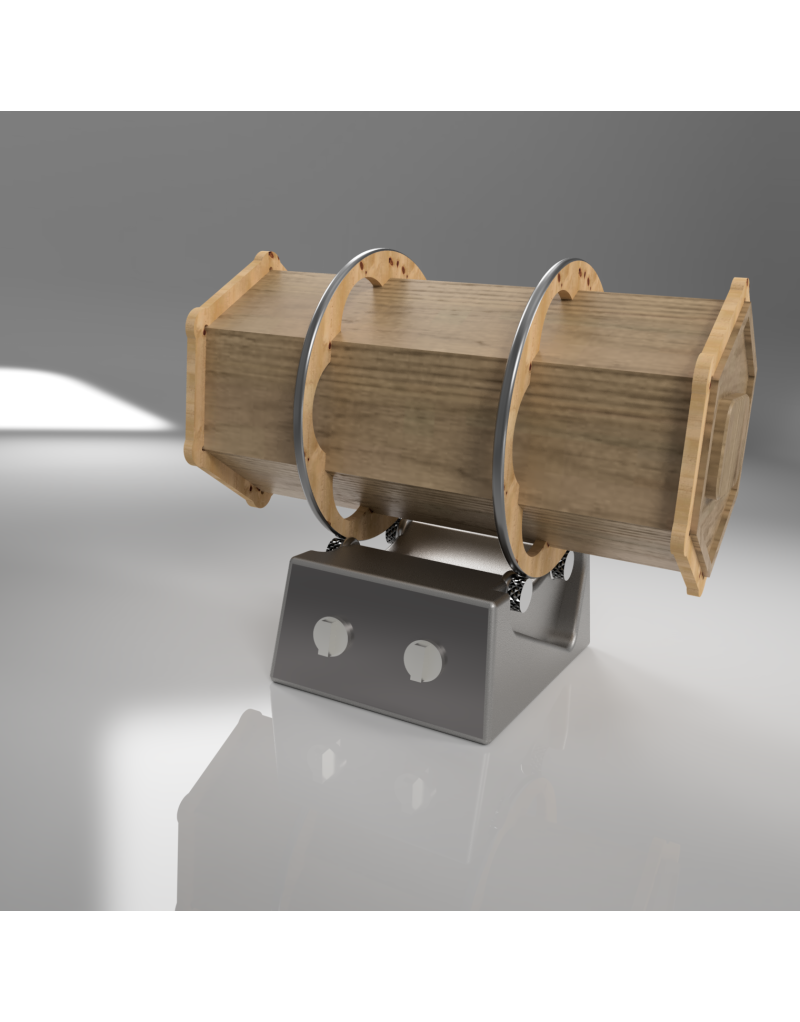

The 2 × 12 eyewear polishing barrel is a professional machine designed for optical workshops to finish acetate eyewear frames. It features a polygonal wooden barrel with two independent compartments, each equipped with its own access hatch, allowing the simultaneous processing of 2 × 12 frames. Engineered for a two-step polishing process, it delivers a uniform satin finish after approximately 48 hours on CNC-machined fronts, followed by final finishing either after 2 days with a polishing wheel, or directly after 5 days of continuous rotation. Operating on 220 V, it consumes only 75 W and includes adjustable speed control for precise process management.

Design and construction

The 2 × 12 eyewear polishing barrel is specifically designed for optical and eyewear workshops requiring full control over the finishing process of acetate frames. The machine features a polygonal wooden barrel, a geometry that promotes continuous and balanced movement of the parts during rotation, ensuring consistent polishing while preserving the material.

The barrel is divided into two fully independent compartments, each equipped with its own access hatch. This design allows different polishing stages or separate frame batches to be processed simultaneously, preventing cross-contamination between polishing media and improving overall workflow efficiency.

Capacity and application

-

Capacity: 2 × 12 eyewear frames

-

Designed for CNC-machined frame fronts

-

Suitable for prototyping, small and medium production runs

Two-step polishing process

1. Roughing / satin finishing stage

This first stage removes machining marks and evens out the acetate surface.

-

Typical duration: approximately 48 hours

-

Result: a uniform satin finish, ready for final polishing

2. Finishing stage

Two finishing strategies are possible depending on workshop organization:

-

Around 2 days in the barrel, followed by a quick final polish on a buffing wheel

-

Approximately 5 days of continuous rotation, achieving a high-gloss polished finish directly from the barrel, with no manual retouching required

Drive system and controls

-

Motor power: 75 W

-

Power supply: 220 V

-

Adjustable rotation speed, allowing precise adaptation of the polishing cycle to the material, media type, and desired surface finish

Key benefits for eyewear manufacturers

-

Very low energy consumption

-

Consistent and repeatable finishing process

-

Reduced manual finishing time

-

High-quality, uniform surface results

-

Durable construction, suitable for intensive workshop use

No customer reviews for the moment.