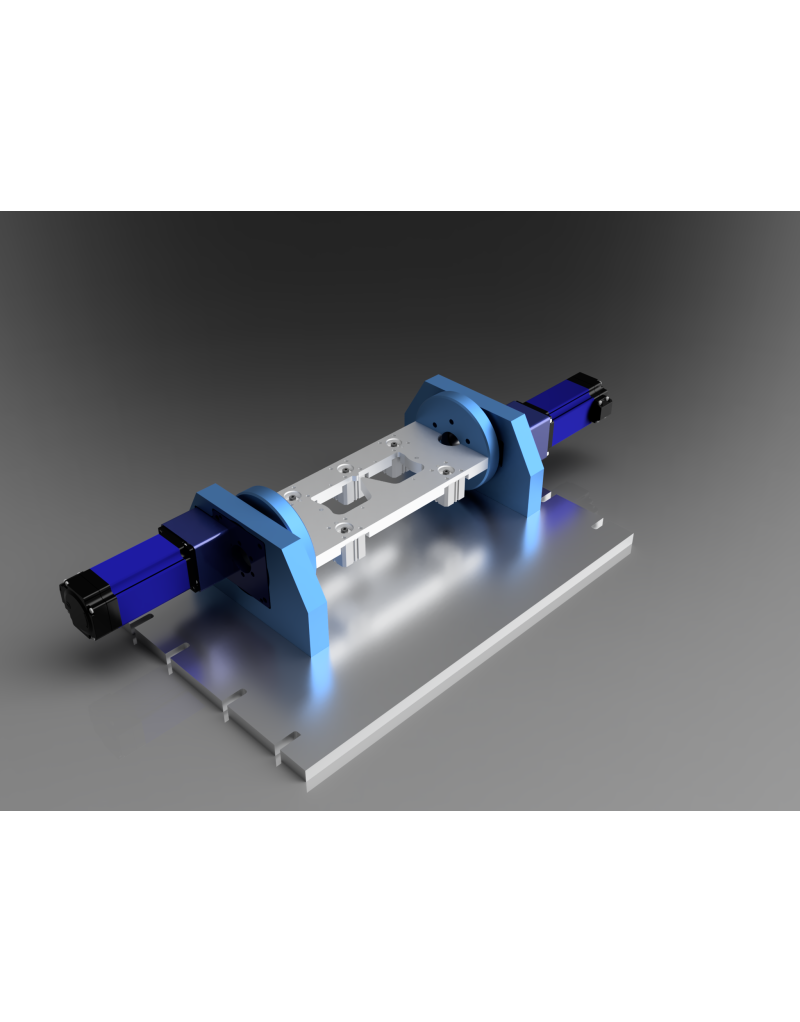

Rotary 4th Axis for Eyewear CNC

Rotary 4th Axis for Eyewear CNC – 7 Nm Servos, Pneumatic Clamping

High-precision 4th rotary axis designed for acetate eyewear manufacturing.

Equipped with 7 Nm servo motors (24–48 V), pneumatic clamping requiring 3–5 bar, and a usable rotation range of 0–90°. Perfect for machining angled hinges and tenons.

Delivered with a Fusion 360 post-processor, a full training video, and a mounting plate for 400×300 mm CNCs. Compatible with any CNC offering at least 150 mm Z-clearance under the gantry.

This rotary 4th axis has been engineered specifically for the precision requirements of acetate eyewear production.

Its 7 Nm servo motors (24–48 V) ensure smooth, accurate and stable rotation, even during the most delicate machining operations.

The system features a pneumatic clamping mechanism tailored for acetate plates, requiring 3–5 bar of compressed air. This fast and secure clamping guarantees optimal holding and safety throughout the machining cycle.

The axis provides a functional rotation range of up to 90°, ideal for machining angled hinges, tenons, and any geometry requiring lateral approach. While a full 180° rotation is technically possible, it is unnecessary for eyewear manufacturing since the part is not accessible from below.

Ready for immediate use, the kit includes:

– a dedicated Fusion 360 post-processor,

– a complete training tutorial,

– a mounting plate for 400×300 mm CNC machines.

Its versatile design also allows installation on any CNC with at least 150 mm of clearance under the gantry.

This 4th axis is the perfect accessory to enhance precision, productivity, and creative capability when machining acetate eyewear frames.

No customer reviews for the moment.