Product Sheet: Armed Temple Blanks

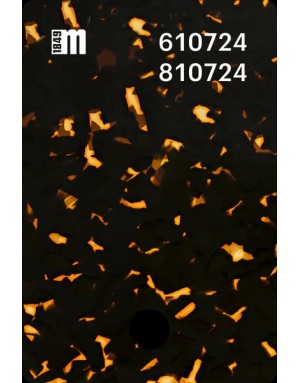

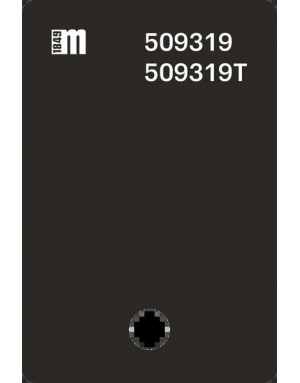

Armed temple blanks equipped with OBE core wire for riveted hinges. Designed for professional acetate eyewear branch manufacturing. Total thickness 6 mm, machinable on both sides. Fusion 360 CNC file included. Available in Black or Tortoise. Sold per pair.

These armed temple blanks are engineered for eyewear workshops seeking precise, ready-to-machine components for acetate temple production.

Each blank is assembled using hot lamination, combining:

-

A 4 mm acetate plate,

-

A 2 mm cover layer,

for a total thickness of 6 mm.

The blank includes a premium OBE core wire, compatible with riveted hinges, ensuring perfect alignment and high mechanical stability while meeting industry standards.

Designed for double-sided machining, the blank can be thinned down to the final desired thickness, typically between 3 and 4 mm, depending on your design requirements.

A CNC machining file (Fusion 360) is provided to integrate directly into your workflow and reduce preparation time.

|

|

Main Features

-

Armed temple blanks

-

Integrated OBE core wire

-

Compatible with riveted hinges

-

Hot lamination (4 mm + 2 mm)

-

Total thickness: 6 mm

-

Double-sided machining

-

Recommended final thickness: 3–4 mm

-

Fusion 360 CNC file included

-

Available colors: Black or Tortoise

-

Sold per pair

Customization

Custom production using your own acetates possible upon request.

Minimum order: 25 pairs.

Pricing

Price indicated per pair.

No customer reviews for the moment.